Project Description

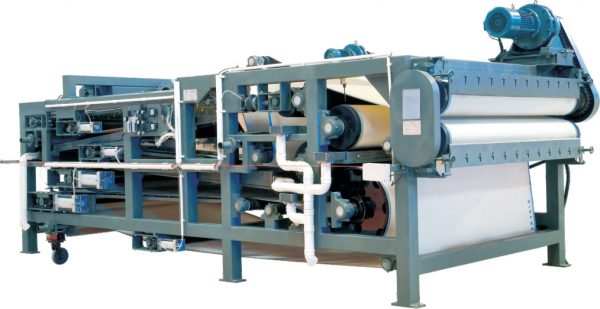

Sludge concentrated extrusion dehydration

Sludge concentrated extrusion dehydration

Applicable to: ceramics, metallurgical mines, coal washing, textile printing and dyeing, urban sewage, paper, petrochemical, leather, brewing, food processing, chemical, pharmaceutical, electroplating and other industries.

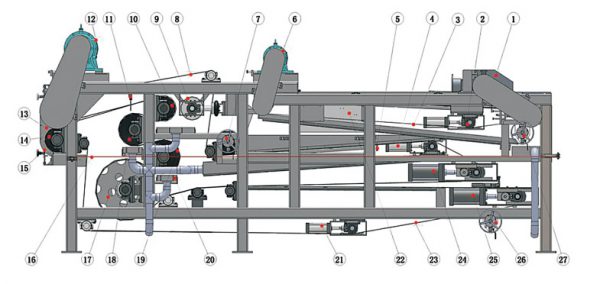

Structure

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Distribution box |

Thickening belt correcting device |

Thickening belt | Upper belt steering device |

Upper belt deviation detective device |

Thickening belt motor |

Belts washing device |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| Upper belt | Twin squeezing rollers |

Squeezing roller Ⅲ |

Over range detective of belt |

Main transmission motor |

Synchronizer gear |

Discharge roller |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| Discharge board |

Safety rope | Safety rope | Squeezing rollerⅡ | Squeezing rollerⅠ | Water collecting tray |

Lower belt deviation steering device |

| 22 | 23 | 24 | 25 | 26 | 27 | |

| Controlling panel |

Lower belt | Upper beg tensioning device |

Lower belt tensioning device |

Belt washing device | Thickening belt washing device |

Types, size and specifications

Type |

Belt width(mm) |

Throughput(m3/h) |

Thickener(kw) |

Main driver(kw) |

Dimension L*W*H(mm) |

Weight (t) |

|---|---|---|---|---|---|---|

| KN1000 | 1000 | 8-15 | 1.1 | 3 | 4700*1600*2180 | 3 |

| KN1500 | 1500 | 15-25 | 1.1 | 4 | 5800*2150*2350 | 4.5 |

| KN2000 | 2000 | 20-35 | 1.5 | 5.5 | 5800*2650*2580 | 6.8 |

| KN2500 | 2500 | 25-40 | 2.2 | 5.5 | 6700*3200*2850 | 10 |

| KN3000 | 3000 | 35-55 | 2.2 | 7.5 | 6700*3700*2850 | 12.5 |

| KS2500 | 2500 | 35-50 | 2.2 | 7.5 | 13000*3200*2850 | 12 |

| KS3000 | 3000 | 45-65 | 3 | 11 | 13000*3700*2850 | 15 |

According to the specific sludge capacity requirement, the width of machine can be chosen from 100Omm-3O0Omm (The choice of thickening belt and filter belt wouldvary/according to different types of sludge). Stainless steel of belt filter press is also available.

It’s our pleasure to offer the most suitable and most economic effective proposal for you according to your project!