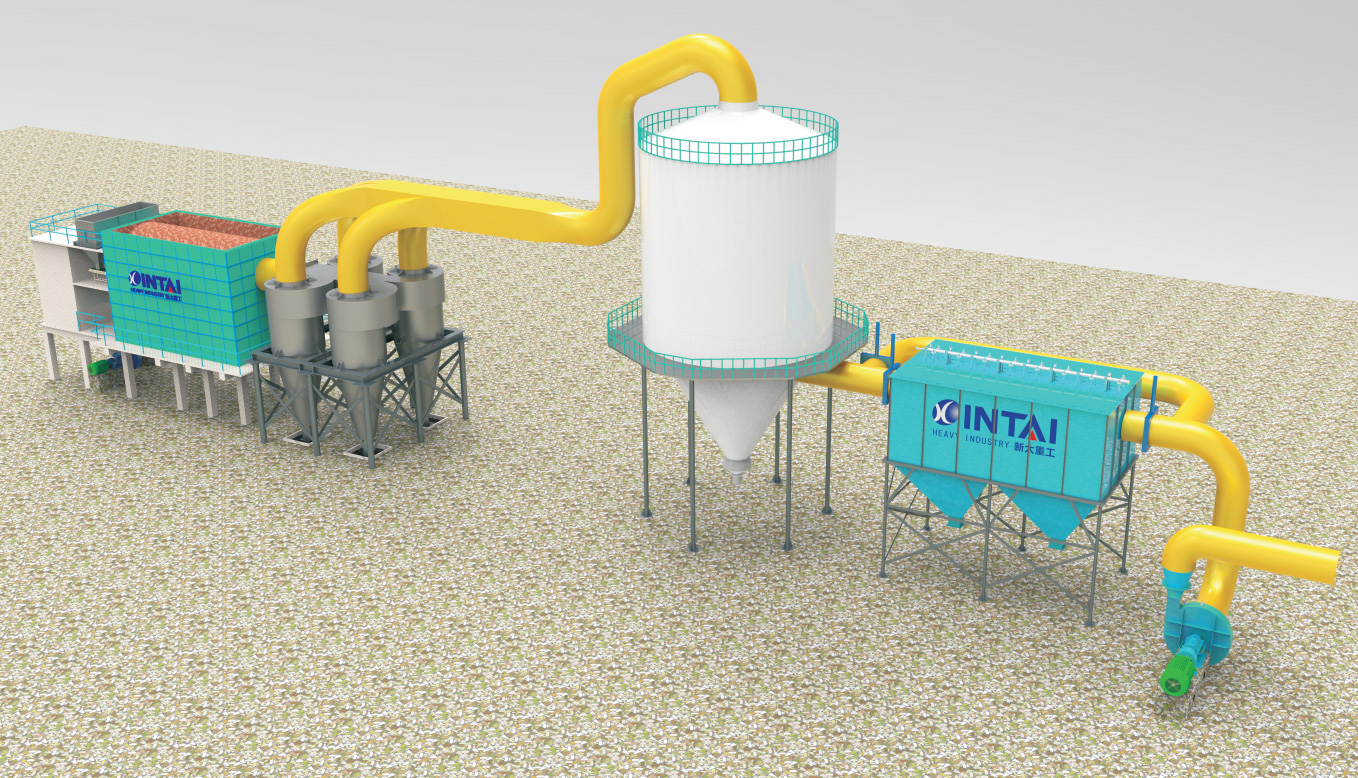

Project Description

Cinder stove

Cinder stove

Cinder stove application

Fluidized bed furnace is widely used in providing heat source for drying and roasting equipments of building materials, chemical industry,

metallurgy

Cinder stove Main performance and characteristic

1. Burning full, high efficiency, reducing coal. Burn-off rate can as high as 98%, thermal efficiency as high as 95%.

2. Coal type is unconstrained and it can use all kinds of solid fuel which Iow heat value higher than 3000kcal/kg such as bituminous coal, anthracite, lignite, gangue, oil shale and bio-fuel etc.

3. Stable, temperature fluctuation is very small.

4. Environmental friendly. Limestone powder is used inside the stove to desulphurization. Sulphur inside coal will be discharge with cinder.Harmful gas becomes less because NO2 is absorbed.

5. Outlet temperature can be adjusted stably between 100℃ to 1050℃ according to different technological requirements.

6. Easy to start up and can be damped down which can as long as 48 hours. It’s unnecessary to restart up after damping down.

7. High degree of mechanization, easy to operate, thermotechnical control intelligentize design.

8. Long service life, little quick-wear part, convenient to maintenance.

Technical parameters

Model |

Capacity(Kcal/h) |

Drying materials |

| FR1.5 | 1.5×10⁶ | Chinese medicine,Lipid powder ,Alumina,PVC,Paraffin,Ceramic powder yellow sand ranks,Slag,Lron concentrate,Coke/LAN carbon,Fiy ash,Calcium carbide slag |

| FR3 | 3×10⁶ | |

| FR3.5 | 3.5×10⁶ | |

| FR5 | 5×10⁶ | |

| FR6 | 6×10⁶ | |

| FR8 | 8×10⁶ | |

| FRL2 | 12×10⁶ | |

| FRL4 | 14×10⁶ | |

| FRL5 | 15×10⁶ | |

| FRL6 | 16×10⁶ | |

| FRL8 | 18×10⁶ | |

| FR25 | 25×10⁶ | |

| FR50 | 50×10⁶ |

3D Design