Project Description

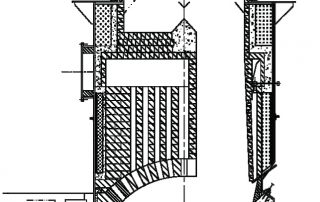

The Third Generation Of Two Stage Coal Gasifier

The Third Generation Of Two Stage Coal Gasifier

.Dry distillation section for refractory cross partition, wet ash discharge The advantages of this kind of furnace type: in the center of the dry distillation section to change the original stainless steel tube structure, replace stainless steel with refractory material, make a cross wall arch structure, retain the advant-ages of good effect of carbonization of dry distillation section, vent on the cross partition distribution, and to further improve, gas production can reach 6500-7000 m ³/h.Maintenance time from originalstainless steel tube structure of 1-2 years extended to5-8 years

Main parameters and technical performance

Name |

Value |

Unit |

Name |

Value |

Unit |

||

| Furnace | Diameter | Ф4000 | mm | Fuel | Coal | Bituminous coal,GB9143-88 | |

| Cross sectional area |

12.56 | m² | Granularity | 13-25,25-50 | mm | ||

| Water jacket |

Heating area |

42.7 | m² | Consumption | 3250-4200 | Kg/h | |

| Working pressure |

0.05 | Mpa | Gas production | 10000-13000 | Nm³/h | ||

| Gas outlet diameter | Ф900 | mm | Gas heating value | 5.44-5.86 | MJ/N M³ | ||

| Air inlet diameter | Ф520 | mm | Air seal steam pressure |

34.3 x 10⁴ | Pa | ||

| Maximum blast pressure |

8200 | Pa | Saturation temperature |

50-65 | ℃ | ||

| Air requirement | 2.8 | Nm³/kg | Water quality requirement of water jacket and air collecto |

Suspended matter |

≤2 | mg/L | |

| Rotational speed of ash tray |

0.121-1.207 | r/h | Total hardness |

≤2.1 | me/L | ||

| Coal feeding system Motor |

3.0 | Kw | PH value (25℃) | ≥6.5-9.5 | |||

| Transmission motor | 15 | Kw | |||||