Project Description

Biomass Gasifier Reactor

Biomass Gasifier Reactor

Coal, oil, natural gas from fossil fuels such ancient creatures,They need to go through millions of years to form and which is nonrenewable resources. Oil, coal, natural gas is not renewable energy, Reserves are limited , they will eventually be replaced by renewable energy.

Biomass is solar energy to chemical energy stored in the living body of energy. Common mainly some larger number, and the more concentrated agricultural waste, such as rice husk, straw, bagasse, corn cob, etc.

Now we have many ways to use biomass, More traditional directburning, but this method is low efficiency, resulting in significantwaste and pollution. Another common use is to create methane, butnot large-scale development.

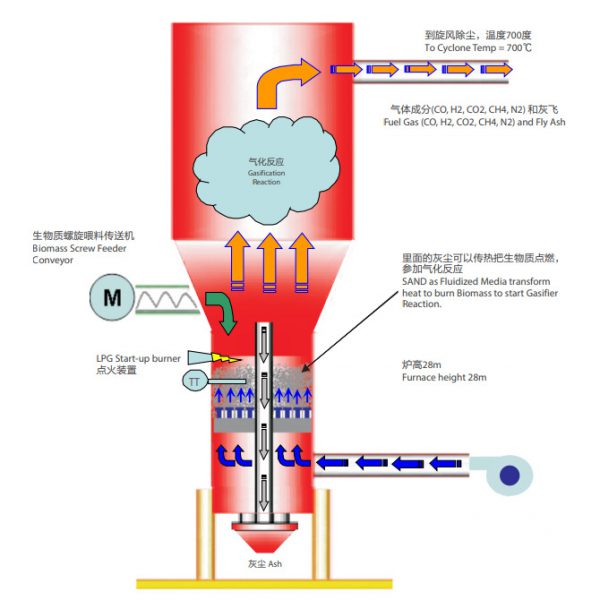

Principles to the use of fluidized bed biomass gasification underhigh temperature conditions into a combustible gas, then Re-use the gas engine or a burner for heating, this is a new way of using biomass and is currently the most promising approach.

Biomass gasification of biomass in principle under the conditions of high temperature and oxygen to decompose and produce flammable gas that is generally known as producer gas, and its in gredients include flammable gases such as H2, CO, CH4 and not flammable gases such as CO2, N2, etc.

Iomass gasification process as part of a useful gas, and part to ashes. Ash addition to field directly, but also can be used for developmentof silicon carbide, sodium silicate and other chemical products.

Gasification:

Partial oxidation process

C6H10O5+水 – >6CO+6H2 Gas phase energetic compounds–> CO, H2, CH4 25-50% O2 needed, 800-1000 oC Air, Oxygen or Steam C6H10O5+ O2 – >5CO+ CO2 +5H2

First developed in 1792 (No Natural Gas and Fuel Oil in that period)

1816 first coal gasification company in the US

1940 Gasification were used in many countries during WWII. Developing stop at 1950 due to introduction of Natural Gas and Fuel Oil

In 1970’s Oil crisis broke out twice worldwide, which accelerated the development of Gasification again.

Gasifier Reactor

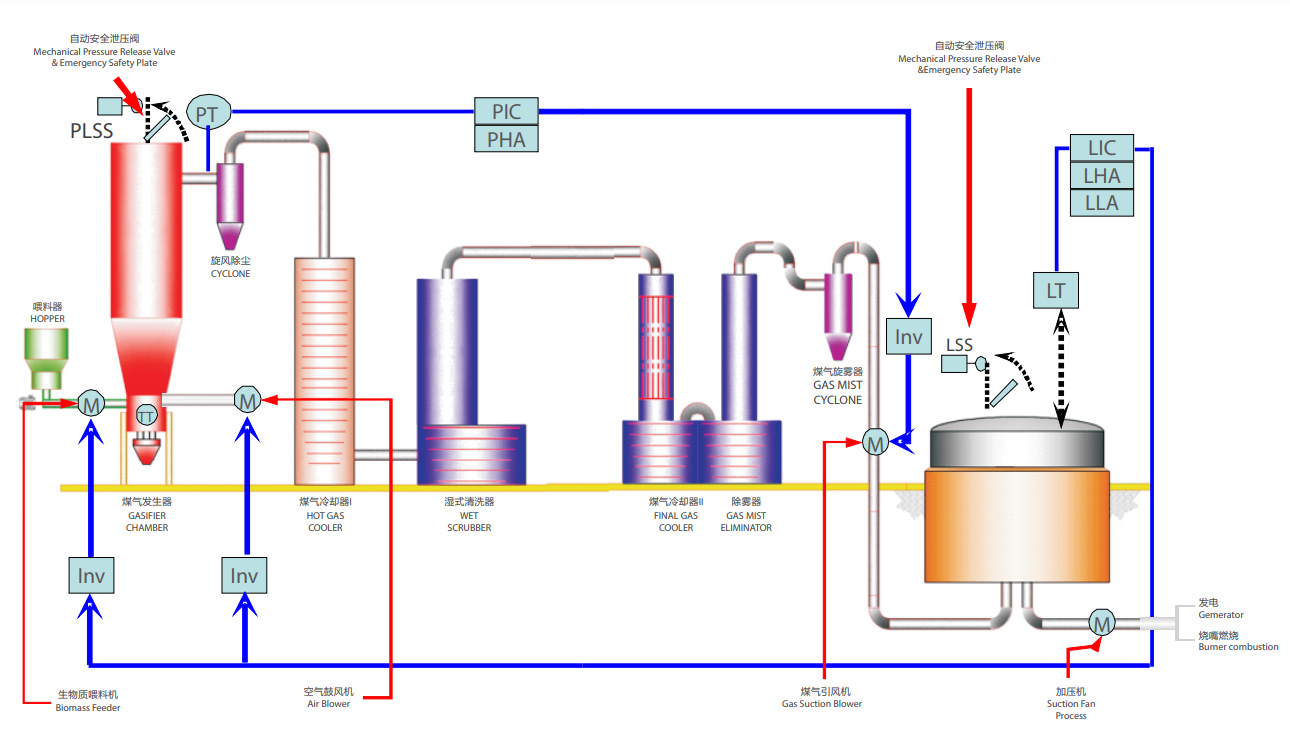

Gasifier process

Biomass Gasifier Model

| Type | 1MW | 5MW | 10MW | 15MW | 20MW | 25MW |

| Maximum gas production | 760m³/h | 3800 m³/h | 7600 m³/h | 11400 m³/h | 15200 m³/h | 19000 m³/h |

| Fuel consumption | Biomass fuel(rice husk、wheat straw、poplar wood、sawdust、paper、rice straw and other biomass) | |||||

| Consumption(approx.) | 320kg | 1600kg | 3200kg | 4800kg | 6350kg | 7900kg |

| Material allows moisture | <10%,<5% is better | |||||

| Gasification efficiency | >70% | >70% | >70% | >70% | >70% | >70% |

| Ash method | Dry ash | Dry ash | Dry ash | Dry ash | Dry ash | Dry ash |

| System control mode | PLC | PLC | PLC | PLC AND SCADA | PLC AND SCADA | PLC AND SCADA |

| Gas Applications | Used burner(Ceramic & chemicals spray dryer hot air generator food processing dryer、paper dryer) | |||||

| Biomass Gas Generator | ||||||

| Ash Applications | Rice Husk Ash have high silica(SiO2) can be used as Raw Material in Ceramic Tiles,Replace Cement,Produce Precipitated Silica, and raw material for fertilizer and soil conditioner. | |||||

Biomass(straw) gen-set

Biomdss generating system is a process which changes biomass waste (wood , straw, chaff, bagasses)to combustible gas, and than generating in internal-combustion engine. The combustible gas of straw are CO, H2,and a small quantity of CH4. Straw gas usually contains coke tar,water and dust, it should have a pretreatment berore entering into gas gen-set.

Bio-gas Power Generation System

Rated Power:30-150KW

Rated speed:1500r/min

Rated frequency:50Hz

Reted voltage:400V

Power factor:0.8

Exciting method:brushless

Voltage regulating mode:automatic

Speed regulating method: Double electronic regulation

System of the power supply: AC 3-Phase,4 wire

Starting system:electric motor

Cooling method:closed water-cooling

Generators

Rated Power:120-500KW

Rated speed:1500r/min

Rated frequency:50Hz

Reted voltage:400V

Power factor:0.8

Exciting method:brushless

Voltage regulating mode:automatic

Speed regulating method:Double electronic regulation

System of the power supply: AC 3-Phase,4 wire

Starting system:electric motor

Cooling method:closed water-cooling

Ash Utilization

| OXIDES | % |

| SiO2 | 68 |

| Al2O3 | 17 |

| TiO2 + Fe2O3 | 6 |

| CaO + MgO | 1 |

| K2O + Na2O | 3 |

| P.F. | 5 |

| TOTAL | 100 |