Project Description

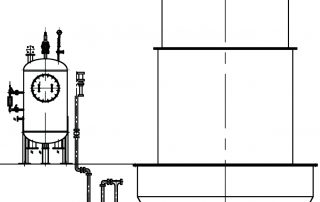

The Fourth Generation Of Two Stage Coal Gasifie

The Fourth Generation Of Two Stage Coal Gasifie

Dry distillation section for refractory cross partition, dry ash discharge The advantages of this kind of furnace type: absorbs the advantages of the first generation and the third generation of furnace type, the wet ash discharge basin structure change to the structure the dry ash discharge without water seal bird-bath, due to remove the water seal, blast furnace bottom pres-sure is not res-tricted by water seal height (wet ash discharge of water seal hei-ght is 8000-10000 MM, so the blast furnace bottom pressure must not exceed 7000 pa.), Up to 10000 pa, so, more to improve gas production, can reach 7500-8000 m³ /h.

Combining the advantages of the third type furnace, carbonization effect is good, the period of the gas does not contain tar, purification equipment blocking phenomenon will not occur Disadvantages: due to dry ash discharge, gas stove to build on a layer of platform, increase a layer of gas station, increased by about 3 meters high, increased investment in infrastructure.

Main parameters and technical performance

Name |

Value |

Unit |

||

| diameter | 3.2 | m | ||

| Cross sectional area | 8.04 | m² | ||

| Heating area | 18 | m² | ||

| Working pressure | 6.4 x 10⁴(0.65) | Pa(kgf/cm²) | ||

| Fuel | F.S.I < 2.5 | |||

| Long flame coal、lignite | ||||

| Bituminous coal,GB50195-94 | ||||

| Granularity | 20 ~40, 25~50 | mm | ||

| Gas production | 7000~8000 | m³/h | ||

| Transmission | Motor | Type | YCT200 – 4B | |

| power | KW 7.5 | |||

| Speed | r/min 125 〜1250 | |||

| Reducer | Type | ZSH50-501 | ||

| Speed ratio | I =49.97 | |||

| Coal feeding system |

Motor | power | 3KW | |

| Maximum blast pressure 8000 – 10000 pa | ||||