Project Description

XTL-Chain Stove

XTL-Chain Stove

XTL-Chain Stove Structure Summarization

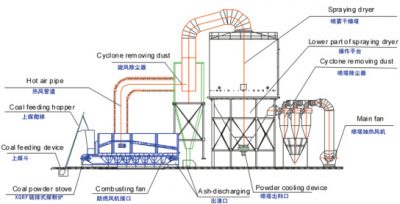

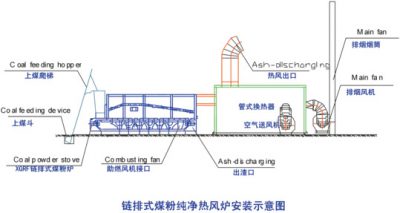

XTL TYPE hot-airstove is composed ofstove main body, coal powder lifter, cyclone or air distributer, electric contr oiling cabinet. The outside

structure is as follows:

Cyclone explanation

One or two cyclone should be equipped according to product requirement to catch the dust in the hot air, one ofsingle central pipe cyclone is for wall tile, its efficiency more than 90%,two sets for polishing tile, its efficiency more than 95%,the central pipe is made of 310S stainless steel to be against high temperature, high aluminum refractory brick is around the cyclone inside wall, The hot air temperature entering cyclone should be lower than 800℃, if higher, should match the cold wind by adjusting cold wind door, by against damage central pipe.

As the water seal is equipped for cyclone, the ash discharge pipe should be checked periodically to avoid injury form ash building up and fall down suddenly

The main technical parameter and equipment list for XTL-TYPE6,TYPE8, TYPE10 Chain Coal Powder Hot-Air Stove

Item |

Type 6 Chain Powder Hot-Air Stove |

Type 8 Chain Powder Hot-Air Stove |

Type 10 Chain Powder Hot-Air Stove |

Type 12 Chain Powder Hot-Air Stove |

Type 14 Chain Powder Hot-Air Stove |

Type 16 Chain Powder Hot-Air Stove |

| Applicable Equipment | Type 2500 Type3200 Drying Tower Powder output:150-200T/day | Type 4000 Type5000 Drying Tower Powder output:250-300T/day | Type 5000 Type6000 Drying Tower Powder output:300-400T/day | Type 6000 Type8000 Drying Tower Powder output:400-500T/day | Type 8000 Type10000 Drying Tower Powder output:500-550T/day | Type 10000 Type12000 Drying Tower Powder output:550-650T/day |

| Applicable Coal Kinds | Soft coal: coal powder combustion calorific value: ≥5500kcal/kg, volatilization content: ≥30%, 2mm≤granularity≤20mm, ash fusion point: >1000℃ combustion<500℃, coal producing area is unlimited. When the coal is high quality, it can be mixed with some miscellaneous coal. | |||||

| The AppearanceSize Stoves | 8000*2000*2000(mm) | 8000*2500*2000(mm) | 8000*3000*2000(mm) | 9000*3500*2000(mm) | 10000*3500*2000(mm) | 9000*4000*2000(mm) |

| Installed Power | 22.2KW | 25.7KW | 33.7KW | 40.7KW | 48.7KW | 58.7KW |

| Chain Width | 1290mm 一set | 1690mm 一set | 2090mm 一set | 2490mm 一set | 2490mm 一set | 2890mm 一set |

| The Wheelbase Grate | 6500mm | 6500mm | 6500mm | 7200mm | 8000mm | 7200mm |

| Reducer | 2.2KW 700 type 1 set | 2.2KW 700 type 1 set | 2.2KW 700 type 1 set | 2.2KW 380 type 1 set | 2.2KW 380 type 1 set | 2.2KW 380 type 1 set |

| CombustionSupporting Fan | 9-26 18.5KW-4 1 set | 9-26 22KW-4 1 set | 9-26 30KW-4 1 set | 9-26 37KW-4 1 set | 9-26 45KW-4 1 set | 9-26 55KW-4 1 set |

| Inverter Brand | Easy to Omron or Fuji | |||||

| Electrical Charging System | 1.5KW 一set | 1.5KW 一set | 1.5KW 一set | 1.5KW 一set | 1.5KW 一set | 1.5KW 一set |

| Cyclone for Glazed Tile | φ1800mm 1 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ2200mm 1 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ3000mm 1 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ3500mm 1 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ3800mm 1 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ4000mm 1 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool |

| Cyclone for Polished Tile | φ1200mm 2 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ1800mm 2 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ1200mm 2 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ3000mm 2 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ3500mm 2 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool | φ3800mm 2 piece, the outside structure as follows A3δ3 steel plate shell δ=115mm refractory brick, air heating pipe stainless steel 310S, the other part inlays thermal insulating wool |